Enhancing Your Product with 3D Printing: Case Studies

renew_57

October 13, 2023

Enhancing Your Product with 3D Printing: Case Studies

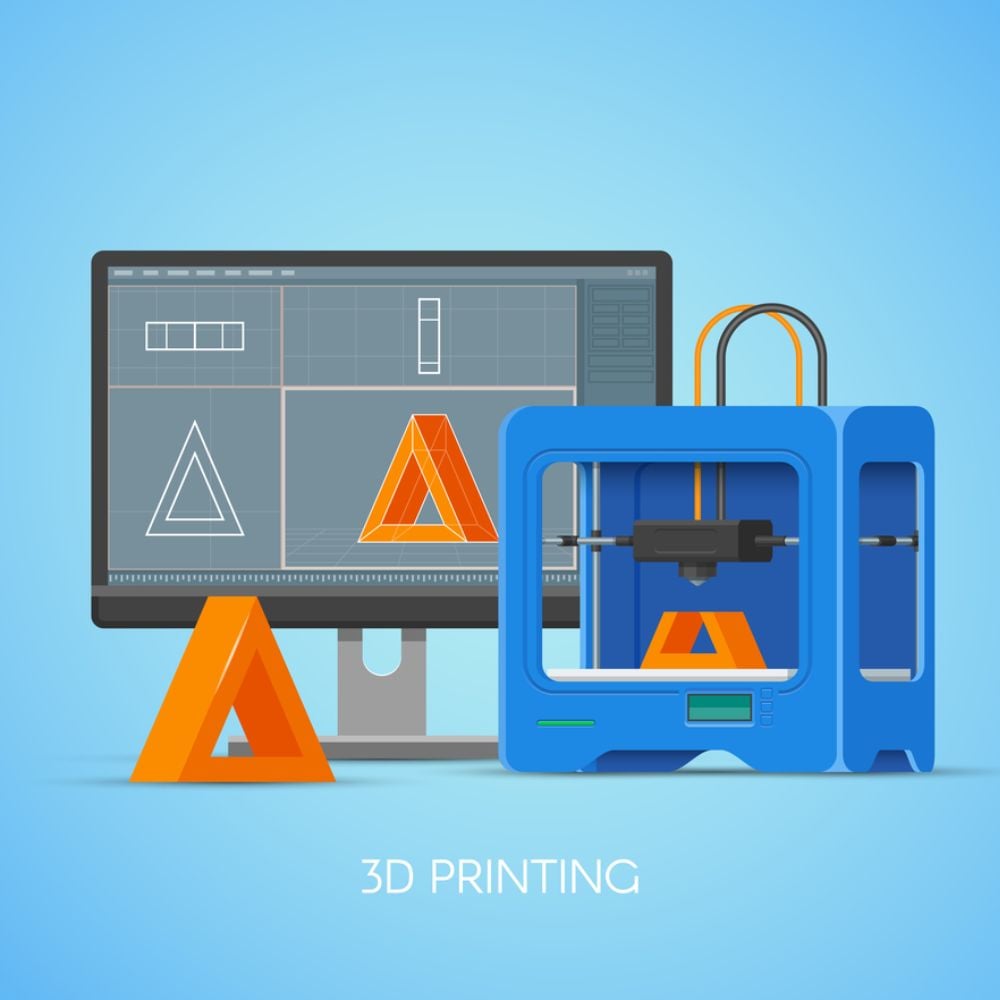

In the world of manufacturing and product development, 3D printing has emerged as a transformative technology that offers unparalleled flexibility and innovation. By harnessing the power of 3D printing, businesses can enhance their products in ways previously unattainable. In this blog, we will explore a few compelling case studies that demonstrate the remarkable impact of 3D printing on product enhancement.

Case Study 1: Aerospace Components

The aerospace industry is known for its stringent requirements for lightweight, high-strength components. Traditional production techniques frequently fail to achieve these requirements. But 3D printing has altered the rules. Engineers and designers are now able to create complex, lightweight parts that are not only strong but also more fuel-efficient. Boeing, for example, has successfully integrated 3D-printed components into their aircraft, reducing weight and improving overall performance.

Case Study 2: Healthcare Prototypes

The healthcare sector has seen incredible advancements in patient care and medical device development thanks to 3D printing. In one notable case, a company called Proximie utilized 3D printing to create highly accurate surgical models. Surgeons could practice complex procedures on these models before performing actual surgeries. This not only improved surgical outcomes but also reduced operating room time and costs.

Case Study 3: Customized Footwear

In the world of fashion and sports, customization is key. Adidas introduced their “Futurecraft 4D” shoes, featuring a 3D-printed midsole tailored to the wearer’s individual needs. This customization ensures optimal comfort and support, leading to improved performance in sports and overall satisfaction for consumers.

Case Study 4: Automotive Prototyping

Automotive companies are leveraging 3D printing for rapid prototyping and design validation. Ford, for instance, used 3D printing to create prototypes of various car components, reducing lead times and costs associated with traditional manufacturing methods. This allows for faster iterations and more innovative designs.

Case Study 5: Jewelry Design

In the world of jewelry design, 3D printing has revolutionized the way intricate and unique pieces are crafted. Jewelers can now bring their intricate designs to life with precision and speed. Companies like Castable Wax 3D Printing have embraced this technology to create stunning and intricate jewelry pieces that were previously impossible to produce.

In conclusion, 3D printing is not just a buzzword; it’s a game-changer in product enhancement across diverse industries. These case studies illustrate how this technology has empowered businesses to create lightweight aerospace components, improve surgical procedures, personalize footwear, streamline automotive prototyping, and elevate jewelry design. Embracing 3D printing can lead to enhanced product quality, reduced costs, and increased customer satisfaction. It’s clear that 3D printing is reshaping the future of product development and manufacturing in remarkable ways.

Recent News

Try Our Services

- RENEW NOW SOLUTIONS INDIA PRIVATE LIMITED 232A, P.P. Poombozhil Nagar, T.M. Voil, Avadi, Chennai, Tamil Nadu, India – 600062

- +91 915 977 9000 / +91 915 967 9000

- renew@renewnowsolutions.com